Foam, with its diverse applications in industries ranging from furniture manufacturing to packaging, demands precision and efficiency in shaping. Enter foam cutting machines – the unsung heroes behind the perfectly sculpted contours and precise circular cuts that bring foam-based products to life. In this blog, we explore two remarkable types of foam cutting machines: the contour cutting machine and the circular cutting machine.

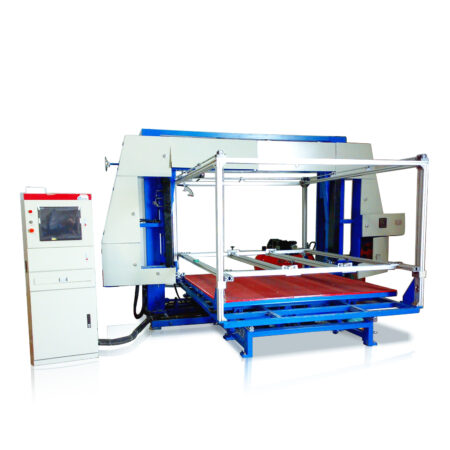

Contour Cutting Machines: Crafting Curves with Precision

Precision Unleashed:Contour cutting machines are the artisans of the foam cutting world, meticulously crafting intricate shapes and curves with unparalleled precision. These machines use advanced technology to follow predefined patterns, ensuring that each cut is exact and consistent. This precision is particularly crucial in industries such as automotive and upholstery, where foam is molded to fit the unique contours of seats and cushions.

|

| contour cutting machine |

What sets contour cutting machines apart is their versatility. Whether it's creating ergonomic designs for mattresses or intricate patterns for decorative applications, these machines can handle a wide range of foam densities and thicknesses. The ability to adapt to various foam types makes contour cutting machines indispensable for industries with diverse foam cutting needs.

Efficiency Redefined:In addition to precision and versatility, contour cutting machines excel in efficiency. The automation of the cutting process not only reduces labor costs but also significantly speeds up production. This efficiency is a game-changer for manufacturers looking to optimize their workflow without compromising on the quality of the final product.

Circular Cutting Machines: Perfecting Rounds with Finesse

A Perfect Circle Every Time:Circular cutting machines are the go-to solution when a foam product demands flawless, uniform circles. From packaging inserts to seat cushions, these machines excel at creating consistent circular cuts with smooth edges. The precision of circular cutting ensures that each piece fits seamlessly into its designated space, contributing to the overall quality of the final product.

|

| Circular cutting machine |

Circular cutting machines are designed to be adaptable, accommodating a variety of foam thicknesses and diameters. This flexibility is invaluable for industries where customization is key. Whether producing small, intricate foam circles for crafts or large, uniform pieces for industrial applications, these machines can be tailored to meet specific requirements.

Speeding Up Production:One of the significant advantages of circular cutting machines is their ability to streamline production processes. The efficiency gained from automated circular cutting not only reduces production time but also minimizes material wastage. This not only contributes to cost savings but also aligns with sustainable manufacturing practices.

In Conclusion: Advancing Foam Crafting to New Heights

As industries continue to evolve and demand more intricate designs and efficient production processes, foam cutting machines like contour and circular cutting machines are at the forefront of innovation. Their ability to combine precision, versatility, and efficiency makes them indispensable tools in the foam fabrication toolkit, shaping the future of foam-based products across various sectors. Whether it's creating a comfortable mattress or a precisely fitted automotive component, these machines play a crucial role in bringing foam to life in its myriad forms.

No comments:

Post a Comment